Concreting in the winter need to be beautiful that time of year, all that snow.

Sakrete

When there have been countless content created about the challenges involving prepared-combined concrete when confronted with cold weather conditions, this article will target on cold temperature concreting suggestions and most effective practices for all those lesser assignments utilizing bagged concrete or connected concrete repair resources. This can assist concrete contractors to hire the proper cold-climate concreting precautions and techniques from the tumble into the spring of any offered year.

Chilly Weather’s Results on Freshly Blended Concrete and Concrete Established Occasions

ACI 306R defines chilly climate as a period when the regular every day temperature falls beneath 40° F for more than 3 consecutive days and the air temperature is not larger than 50° F for additional than one particular-fifty percent of any 24-hour cycle during the period of time.

When h2o and portland (hydraulic) cement are blended, a chemical response takes place which releases warmth, known as the “heat of hydration”. This exothermic response places the placing of concrete in motion as well as the advancement of concrete toughness, known as maturity. Lessen temperatures slow down the cement hydration system, ensuing in delayed established times and lessened compressive toughness of concrete at its previously ages.

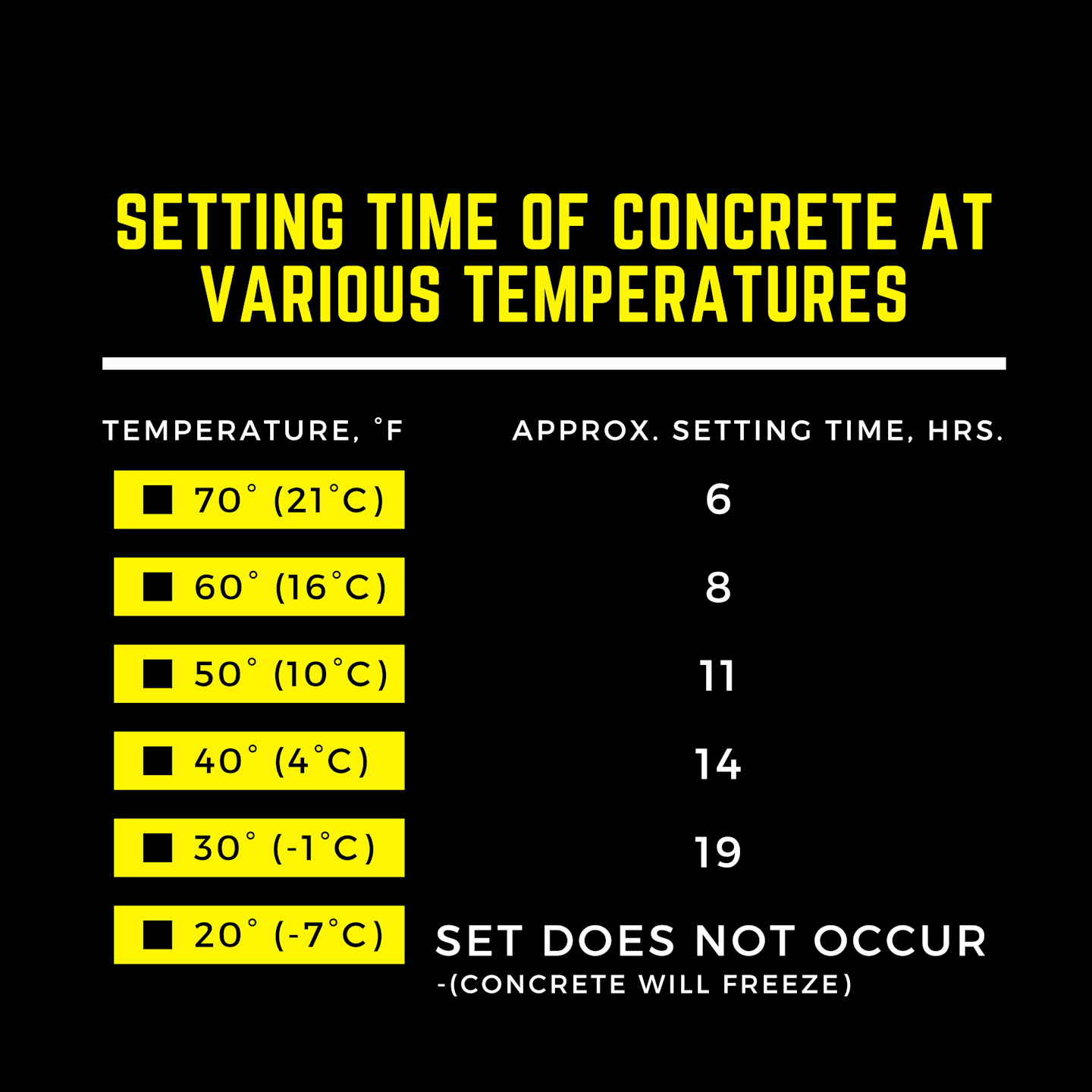

The approximate location time for concrete boosts as the temperature drops. Prepare forward.Sakrete

The approximate location time for concrete boosts as the temperature drops. Prepare forward.Sakrete

The exceptional temperature for concrete is 70° F. We can see from this chart that when the temperature drops to 40° F, the set time extra than doubles from placement to ultimate ending. Bear in thoughts that these scientific studies and reviews, these kinds of as the chart demonstrated previously mentioned, replicate the placement of completely ready-blended concrete all through colder temperatures. There is a lot more mass in 1 cubic yard of concrete as in contrast to the .6 cubic toes generate from an 80-pound bag of concrete blend. This suggests there is a good deal significantly less warmth created when mixing bagged concrete as as opposed to that poured from a ready-mixed concrete truck. Because of to the smaller mass becoming positioned, one should anticipate the set periods for bagged concrete placement to basically choose extended than the “Concrete Established Time and Temperature” chart signifies in cold weather conditions.

Just before the Pour and Foremost Up to the Placement

- Know the neighborhood temperature forecast, noting the ambient air temperature, humidity, and wind speeds the working day of the career, and the 7-day weather conditions forecast next the pour.

- Get ready the subgrade, or prep the concrete to be fixed the day in advance of placement and set the sorts.

- Cover the subgrade or area to be fixed with insulating supplies to maintain the area and kinds warm. Take away the insulating supplies just right before the software of concrete or linked components.

- Pick out your wintertime blend and other materials for the job.

- Keep your products in a dry and warm conditioned area if doable, as opposed to leaving the components exposed on the occupation-web page.

- Never ever pour concrete or utilize concrete fix materials on frozen floor or substrate, or if freezing temperatures will take place within just 48 hours.

- Preserve an infrared thermometer helpful to test surface and content temperatures.

- Over all, if the air temperature is far too very low or the place is going through serious inclement temperature, delay the placement.

Deciding on the Right Combine for Chilly Climate

As air temperature drops, so does the ground temperature. In the situation of a footing or post hole, you have the soil bordering the concrete to look at. When pouring a slab, the sorts and the stone foundation arrive into engage in. In these situations, the position-website components all take in heat from the freshly combined and positioned concrete.

There are three strategies to improve your “winter mix” to assistance optimize warmth of hydration in colder temperatures. Possibly use a concrete bagged blend with a greater cement articles, transform to a blend with a more reactive, a lot quicker-placing cement, or equally. To carry out this, take into account upgrading to Sakrete 5000 Furthermore Concrete Mix for the larger cement content material or applying Sakrete Fast Setting Concrete Mix for a speedier set.

For those heavier industrial or industrial assignments, or you want the finest of each worlds, consider gain of the better cement contents and specific cement blends like Sakrete Pro-X 180 Concrete Combine or Sakrete Professional-Combine Accelerated Concrete Blend.

Considerations for Chilly Climate Concrete Content Mixing

Picking out the right mix for chilly weather will assistance the concrete to conduct better in reduce temperatures, but it does not transform the actuality that it could continue to be also chilly to “jumpstart” the warmth of hydration. Right here are techniques to aid deliver warmth to start out the location process:

- When mixing concrete or fix resources, area at the least expensive slump doable, i.e. pour a drier combine. This is finished by simply just incorporating significantly less water when mixing. Significantly less h2o means a decreased h2o-to-cement ratio, which will shorten the set time of the concrete, lessen the bleed water on the area, and end result in a much better, additional tough concrete.

- Think about including a flow maximizing admixture to aid slash back on the water, though assuring a looser and easier to place blend.

- When placing posts, make use of Sakrete Rapid Environment Concrete Combine in lieu of standard concrete and truly blend the concrete ahead of pouring into the hole.

- Use heat drinking water to combine the concrete. Heating water is the most practical and simplest means for expanding concrete temperature. Incredibly hot water from the faucet frequently does not exceed 120° F. This is sufficient to warming the concrete more than enough to bring about the cement hydration response. Do not include boiling h2o to concrete. This most probable will lead to a flash set. In addition, latex additives to mend items or specialized concrete may soften at temperatures earlier mentioned 180° F.

- Calcium chloride is the most frequent accelerating admixture. Under no circumstances insert more than 2% dosage by pounds of cement. When using bagged concrete or concrete restore materials it is clever to acquire a premixed remedy of calcium chloride, these kinds of as Sakrete Cement Mix Accelerat

or, to aid meter a suitable dosage of the accelerator. Do not insert chloride-containing accelerators to concrete that will incorporate metal reinforcement or that will fulfill metallic. Chloride ions tremendously enhance the prospective for corrosion. - Non-chloride, non-corrosive accelerators are an alternate to chloride accelerators. These are much less reactive than calcium chloride, but do not harm embedded reinforcement metals in the concrete. When setting up on using a non-chloride accelerator with concrete restore materials or specialised, large general performance bagged concretes, combine a examination batch. Some non-chloride bases are not reactive with mixes that contains a CSA cement.

- Never ever increase automotive antifreeze or windshield washer wintertime system to concrete. These merchandise do not give “anti-freeze” homes to concrete. That is a building fantasy and negatively impacts the longevity and best toughness of the concrete.

Security After the Pour

ACI 306.1-90 endorses shielding clean concrete from the factors for at the very least 3 times after placement, managed at 50°F. The stage is concrete can freeze after placement. Concrete requirements to be protected until finally it reaches a minimum amount compressive strength of 500 PSI [3.5 MPa]. Plastic concrete that freezes might go through lowered power by 50% and its toughness will be adversely impacted.

Do not rely on warmth produced by cement hydration to secure clean concrete from freezing. A calcium chloride accelerator is not a concrete anti-freeze.

Some simple approaches for fresh new concrete security in the course of cold weather are:

- Go away sorts in position for 1 to 7 times, based mostly on the severity of the cold weather conditions adhering to the placement. This will assist distribute heat evenly as a result of the concrete.

- Soon after the concrete is completed, contemplate making use of membrane-forming curing compounds, these as Sakrete Concrete Heal N’ Seal.

- Protect the floor with insulating components this kind of as rigid board insulation, insulated curing blankets or tarps, or plastic sheeting included by straw. For the straw method, make positive to area a fantastic 12-inches or much more layer of straw and top rated with one more sheet of plastic.

- For any of these insulating strategies, bear in mind to weigh down the top rated of the components to continue to keep excessive drinking water out and the insulating materials from blowing off the concrete.

- The same attention to cold weather security provided to slabs need to be given to slim sections of concrete or cementitious repairs, as thinner sections are hugely vulnerable to freezing hurt.

- The moment the concrete matures, steadily clear away the components to stay clear of thermal shock.

Despite the fact that cold climate concrete placement poses its worries, if done adequately, concrete placed at lessen temperatures will profit from the slower curing periods. This effects in a concrete that will produce larger ultimate energy and improved durability.

If you are more recent to concrete or simply would like to know additional about chilly climate and the worries it poses for concrete, a very good place to start is by looking through the American Concrete Institute Regular Advised Follow for Cold Weather Concreting (ACI 306R).

Dirk Tharpe, Sakrete Concrete QualifiedSakreteDirk Tharpe has spent his qualified daily life in the ready-mixed concrete, masonry, and concrete fix products industries. He now functions with Oldcastle APG representing the Sakrete, Amerimix, and Belgard manufacturers. Sakrete concrete, concrete mend, and mortars have the suitable Professional-Quality products for any challenge and a focused workforce of Technical Services Experts to aid. Oldcastle APG, a CRH organization, is a person of the leading vendors of outdoor living and creating solutions. Oldcastle APG belongs to CRH’s Setting up Products division. CRH is a top worldwide diversified creating elements team, employing roughly 77,600 persons at around 3,100 operating destinations in 31 countries throughout the world.

Dirk Tharpe, Sakrete Concrete QualifiedSakreteDirk Tharpe has spent his qualified daily life in the ready-mixed concrete, masonry, and concrete fix products industries. He now functions with Oldcastle APG representing the Sakrete, Amerimix, and Belgard manufacturers. Sakrete concrete, concrete mend, and mortars have the suitable Professional-Quality products for any challenge and a focused workforce of Technical Services Experts to aid. Oldcastle APG, a CRH organization, is a person of the leading vendors of outdoor living and creating solutions. Oldcastle APG belongs to CRH’s Setting up Products division. CRH is a top worldwide diversified creating elements team, employing roughly 77,600 persons at around 3,100 operating destinations in 31 countries throughout the world.

More Stories

Real Estate Agents – What to Look for in a Mentor

Typical Workday of a Real Estate Agent

What You Can Expect To Pay A Playa Del Carmen Realtor